The Future of LPG Hoses: Trends to Watch for Enhanced Safety and Efficiency

Release time:

2025-08-18

Author:

Source:

Abstract

The Future of LPG Hoses: Trends to Watch for Enhanced Safety and Efficiency

As the world increasingly turns towards efficient and sustainable energy solutions, the role of Liquefied Petroleum Gas (LPG) is becoming ever more prominent. LPG hoses are a crucial component in the safe transport of this energy source. Understanding the future trends in LPG hoses is essential for manufacturers, suppliers, and users alike. This article will explore the innovations, trends, and technology influencing the future of LPG hoses, focusing on safety, efficiency, and environmental sustainability.

Table of Contents

- 1. Introduction to LPG Hoses

- 2. Importance of Quality in LPG Hoses

- 3. Key Trends Influencing LPG Hoses

- 3.1 Material Innovations in LPG Hoses

- 3.2 Technological Advancements in Hose Design

- 3.3 Regulatory Changes Impacting LPG Hose Manufacturing

- 3.4 Sustainability in LPG Hose Production

- 3.5 The Rise of Smart LPG Hoses

- 4. The Role of Safety in LPG Hose Design

- 5. How to Choose the Right LPG Hose

- 6. The Future of LPG Hoses: What to Expect

- 7. Conclusion

- 8. FAQs

1. Introduction to LPG Hoses

LPG hoses are essential for the safe and efficient transport of liquefied petroleum gas, which is widely used in residential, commercial, and industrial applications. These hoses must be durable, flexible, and resistant to various environmental factors, including temperature fluctuations and chemical exposure. As the demand for LPG continues to grow, so does the need for high-quality hoses that ensure safe handling and transport.

2. Importance of Quality in LPG Hoses

The quality of LPG hoses plays a vital role in the overall safety and efficiency of gas handling operations. High-quality hoses can withstand pressure variations and extreme temperatures, minimizing the risk of leaks and accidents. Furthermore, investing in robust and reliable hoses can significantly reduce maintenance costs and downtime, ensuring uninterrupted service in various applications.

3. Key Trends Influencing LPG Hoses

The landscape of LPG hoses is continuously evolving. Here, we discuss several key trends that are shaping the future of LPG hoses, focusing on materials, technology, regulatory updates, sustainability, and smart solutions.

3.1 Material Innovations in LPG Hoses

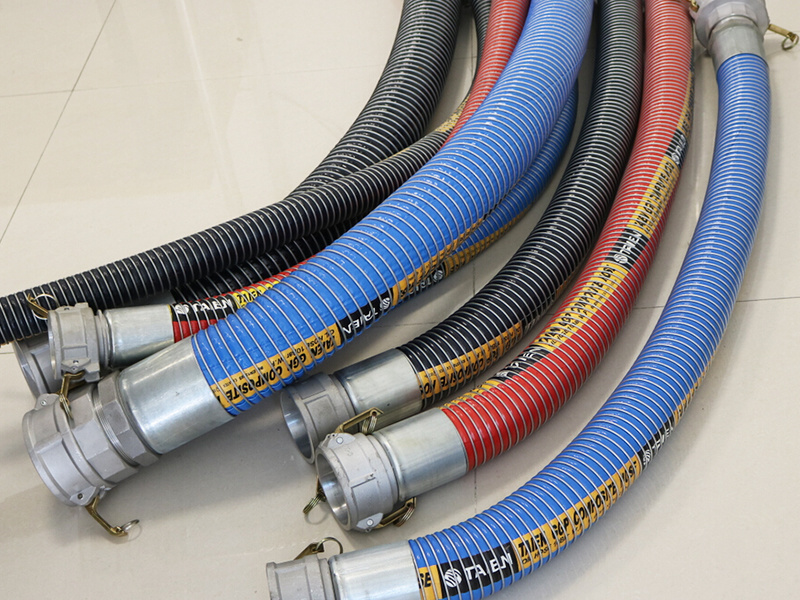

One of the most significant trends in the LPG hose industry is the innovation of materials used in hose manufacturing. Traditional rubber hoses are now being replaced with advanced materials such as thermoplastics and composite materials. These materials offer enhanced durability, resistance to abrasion, and flexibility, making them suitable for a wide range of applications.

Moreover, new manufacturing techniques such as extruded and molded thermoplastic hoses allow for tighter tolerances, improving overall performance and safety. The use of lightweight materials also helps reduce transportation costs and enhance ease of handling.

3.2 Technological Advancements in Hose Design

Technology is playing an increasingly critical role in the design and production of LPG hoses. Manufacturers are leveraging computer-aided design (CAD) software and 3D modeling to create more efficient hose designs. These advanced design tools enable engineers to simulate various conditions and optimize the performance of hoses before they are manufactured.

Additionally, the integration of advanced manufacturing techniques, such as injection molding and automated assembly lines, has improved production efficiency and reduced costs, ultimately benefiting end-users.

3.3 Regulatory Changes Impacting LPG Hose Manufacturing

The LPG industry is subject to rigorous regulations to ensure safety and environmental responsibility. As regulatory bodies introduce new standards, LPG hose manufacturers must comply with updated specifications. Compliance with these regulations not only ensures safety but also maintains the integrity of the industry.

Recent changes have focused on increasing safety standards, particularly in the areas of pressure resistance and leak testing. Manufacturers are now required to provide certification that their products meet these stringent guidelines, which reinforces the market's commitment to safety.

3.4 Sustainability in LPG Hose Production

With an increasing emphasis on sustainability, manufacturers are exploring eco-friendly materials and production methods. The shift towards recyclable and biodegradable materials reflects a broader industry trend towards reducing environmental impact.

Additionally, companies are adopting sustainable manufacturing practices, such as reducing waste during production and improving energy efficiency in their operations. By prioritizing sustainability, manufacturers not only comply with regulatory pressures but also appeal to environmentally conscious consumers.

3.5 The Rise of Smart LPG Hoses

The advent of the Internet of Things (IoT) is transforming various industries, and LPG hose manufacturing is no exception. Smart LPG hoses equipped with sensors can monitor pressure, flow rates, and temperature in real-time, providing valuable data that can help prevent leaks and failures.

These smart solutions can enhance safety by alerting operators to potential issues before they escalate into dangerous situations. Furthermore, the data collected can be used for predictive maintenance, optimizing operational efficiency, and reducing downtime.

4. The Role of Safety in LPG Hose Design

Safety is paramount in the design and manufacture of LPG hoses. The potential risks associated with gas leaks, explosions, and other hazardous incidents necessitate a rigorous approach to hose design. Manufacturers are implementing various safety features, including:

- Reinforcement layers to withstand high pressures

- Anti-static properties to prevent sparks

- Specialized fittings that ensure secure connections and minimize leaks

Regular testing and compliance with safety standards are critical to ensure that hoses can withstand extreme conditions and operate safely over their intended lifespan. The focus on safety not only protects users but also enhances the reputation of manufacturers in the marketplace.

5. How to Choose the Right LPG Hose

Choosing the right LPG hose is crucial for maintaining safety and efficiency in gas handling operations. Here are several factors to consider when selecting an LPG hose:

- Material Compatibility: Ensure that the hose material is compatible with the type of LPG being used.

- Pressure Rating: Select a hose with a pressure rating suitable for your application.

- Temperature Range: Consider the temperature fluctuations the hose will be exposed to during operation.

- Length and Diameter: Choose the appropriate length and diameter based on your installation requirements.

- Regulatory Compliance: Ensure the hose meets all relevant safety and performance standards.

Investing time in selecting the right hose can significantly enhance the safety and efficiency of LPG handling operations.

6. The Future of LPG Hoses: What to Expect

The future of LPG hoses looks promising, as ongoing innovations and trends continue to shape the industry. Advancements in materials, design, and technology will likely lead to the development of more efficient, durable, and safe hoses.

Moreover, the increasing focus on sustainability and environmental responsibility will drive manufacturers to adopt greener practices and materials. As smart technology becomes more prevalent, the integration of monitoring systems will enhance operational safety and efficiency.

As the energy landscape evolves, LPG hoses will play an integral role in supporting this transition while ensuring the highest safety standards are maintained.

7. Conclusion

In conclusion, the future of LPG hoses is marked by significant innovations and trends that enhance their safety, efficiency, and sustainability. From advanced materials and technological integrations to regulatory compliance and environmental considerations, the LPG hose industry is evolving to meet the demands of a changing energy landscape. By staying informed and adapting to these changes, manufacturers and users can ensure safe and efficient gas handling operations in the years to come.

8. FAQs

What materials are commonly used in LPG hoses?

Common materials include rubber, thermoplastics, and composite materials, each offering unique advantages in terms of durability, flexibility, and resistance to environmental factors.

How often should LPG hoses be inspected?

LPG hoses should be inspected regularly for signs of wear, damage, or leaks. It’s advisable to conduct thorough checks annually and after any significant usage or exposure to extreme conditions.

Are there specific regulations governing LPG hoses?

Yes, there are various regulations and standards that govern the manufacturing and use of LPG hoses. Compliance with these standards is essential for ensuring safety and reliability.

What should I do if I suspect a leak in my LPG hose?

If you suspect a leak, immediately turn off the gas supply, evacuate the area, and contact a professional for assistance. Do not attempt to repair the hose yourself.

How can I ensure the longevity of my LPG hoses?

To ensure longevity, choose high-quality hoses, conduct regular inspections, store them properly, and avoid exposure to harsh chemicals or extreme temperatures.

By understanding these trends and making informed decisions, stakeholders in the LPG industry can navigate the evolving landscape and remain at the forefront of safety and efficiency in gas handling.

Recommended Reading