The Importance of Quality in Marine Hose Manufacturing: Ensuring Safety and Efficiency at Sea

Release time:

2025-08-21

Author:

Source:

Abstract

The Importance of Quality in Marine Hose Manufacturing

The marine industry relies heavily on durable and efficient equipment for effective operation. One crucial component in this equation is the **marine hose**. A quality marine hose is not just a piece of equipment; it is a lifeline that ensures safety, efficiency, and optimal performance at sea. This article delves into the significance of qual

The Importance of Quality in Marine Hose Manufacturing

The marine industry relies heavily on durable and efficient equipment for effective operation. One crucial component in this equation is the **marine hose**. A quality marine hose is not just a piece of equipment; it is a lifeline that ensures safety, efficiency, and optimal performance at sea. This article delves into the significance of quality in marine hose manufacturing, exploring how it affects maritime operations and the broader implications for safety and efficiency.

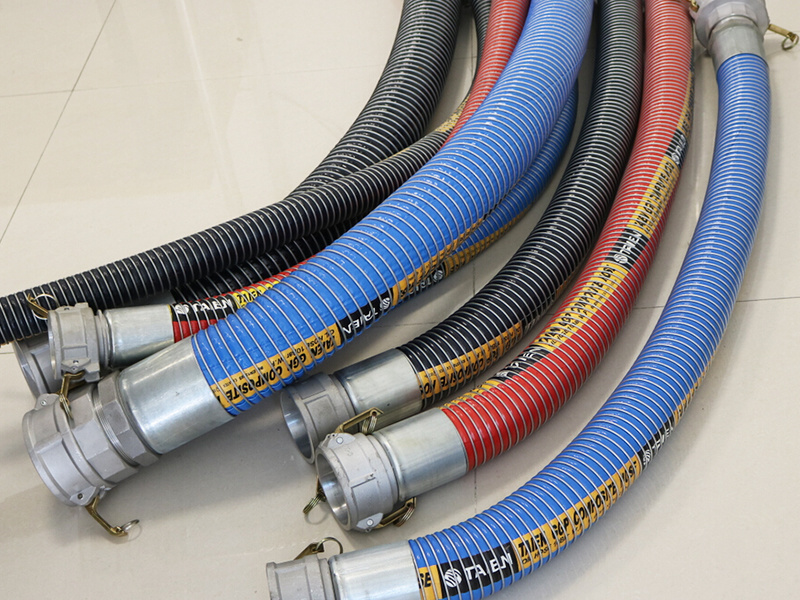

Understanding Marine Hose: An Overview

Marine hoses are specialized hoses designed to transport fluids in maritime environments. They are used extensively in various applications, including fuel transfer, ballast systems, and wastewater management. Given the challenging conditions at sea, these hoses must withstand high pressures, abrasive materials, and extreme weather.

Key Characteristics of Quality Marine Hoses

To fulfill their demanding roles, quality marine hoses possess several key characteristics:

1. **Durability**: They must endure harsh marine environments, including saltwater exposure, UV radiation, and extreme temperatures.

2. **Flexibility**: Marine hoses should be flexible enough to manage dynamic movements without kinking or breaking.

3. **Pressure Resistance**: They must handle high-pressure applications safely, ensuring that they do not burst or leak.

4. **Chemical Resistance**: Marine hoses frequently transport various chemicals, making it essential for them to resist corrosion and degradation.

5. **Safety Standards Compliance**: Quality marine hoses adhere to established industry standards and certifications, ensuring they are fit for the intended purpose.

The Manufacturing Process of Quality Marine Hoses

Understanding the manufacturing process of marine hoses reveals the intricacies involved in creating a high-quality product.

Material Selection

The selection of materials is foundational in marine hose manufacturing. Quality hoses utilize advanced polymers, synthetic rubber, and reinforced materials that enhance performance and longevity. These materials must be resistant to UV rays, chemicals, and mechanical wear.

Design and Engineering

Quality also stems from rigorous design and engineering processes. Engineers use advanced computer-aided design (CAD) software to create precise specifications that optimize performance. Innovative designs often incorporate features like spiral reinforcement to enhance strength and flexibility.

Manufacturing Techniques

The manufacturing process typically involves the following steps:

1. **Extrusion**: The selected materials are heated and forced through a die to create the hose body.

2. **Reinforcement**: Layers of reinforcement, such as textiles or wires, are added to bolster the hose against external forces.

3. **Curing**: The hose undergoes a curing process to improve its structural integrity and establish the desired properties.

4. **Quality Control**: Each batch of hoses undergoes rigorous testing to ensure it meets safety and performance standards. This includes pressure testing, bend testing, and chemical resistance evaluations.

Importance of Quality Control in Marine Hose Manufacturing

Quality control is an indispensable part of marine hose manufacturing. It ensures that every hose produced can withstand the rigorous demands of marine operations. Without a robust quality control process, manufacturers risk producing hoses that may fail, leading to catastrophic consequences.

The Role of Certifications and Standards

In the marine industry, certifications and standards serve as benchmarks for quality. Organizations like the American Bureau of Shipping (ABS) and the International Maritime Organization (IMO) set forth guidelines that marine hoses must meet. Compliance with these standards not only enhances safety but also boosts the credibility of manufacturers.

Impact of Quality on Safety

Safety is paramount in maritime operations. Quality marine hoses significantly reduce the risk of leaks and failures, which can lead to hazardous spills, environmental damage, and injuries. Ensuring that hoses meet stringent quality standards is essential to maintaining a safe working environment for maritime personnel.

Impact of Quality on Efficiency

Quality also directly correlates with operational efficiency. Hoses that are durable and reliable reduce downtime and maintenance costs. When marine hoses perform optimally, the entire operational process becomes smoother, allowing for quicker turnarounds and improved productivity.

Best Practices for Ensuring Quality in Marine Hose Manufacturing

To maintain high-quality standards in marine hose manufacturing, several best practices should be employed:

Continuous Training and Development

Investing in ongoing training for employees can enhance the quality of manufacturing processes. By ensuring that staff are knowledgeable about the latest technologies and practices, manufacturers can improve overall product quality.

Investing in Technology

Utilizing advanced manufacturing technologies can significantly impact the quality of marine hoses. Automation and precision engineering minimize human error and enhance consistency in production.

Regular Maintenance and Inspections

Implementing a program for regular maintenance and inspections of both equipment and finished products is essential. This proactive approach can identify potential issues before they result in failures.

Case Studies: Success Stories in Quality Marine Hose Manufacturing

Examining successful case studies can provide valuable insights into the importance of quality in marine hose manufacturing.

Company A: Pioneering Durability

Company A revolutionized marine hose production by incorporating cutting-edge materials that significantly enhanced durability. Their hoses have set new industry benchmarks, showcasing the value of investing in quality.

Company B: Commitment to Safety

Company B implemented rigorous testing protocols that exceed industry standards. Their commitment to safety has resulted in zero incidents related to hose failures, demonstrating how quality control can directly enhance safety in marine operations.

FAQs About Marine Hose Quality

What makes a marine hose high-quality?

A high-quality marine hose is characterized by its durability, flexibility, pressure resistance, chemical resistance, and adherence to safety standards.

How often should marine hoses be inspected?

Marine hoses should be inspected regularly, ideally before each use, to identify any signs of wear, damage, or deterioration.

What are the consequences of using low-quality marine hoses?

Using low-quality marine hoses can lead to leaks and failures, posing safety hazards and leading to costly downtime and environmental damage.

Are there certifications for marine hoses?

Yes, marine hoses can receive certifications from organizations such as the American Bureau of Shipping (ABS) and the International Maritime Organization (IMO) to ensure compliance with industry standards.

How can I ensure I’m purchasing a quality marine hose?

To ensure you're purchasing a quality marine hose, look for reputable manufacturers that adhere to established safety standards and have a solid track record in the industry.

Conclusion

The importance of quality in marine hose manufacturing cannot be overstated. High-quality marine hoses are vital for safety, efficiency, and overall operational effectiveness in maritime environments. With rigorous manufacturing processes, stringent quality control measures, and adherence to industry standards, manufacturers can produce hoses that meet the demanding needs of the marine industry. By prioritizing quality, we not only enhance safety and efficiency but also contribute to the sustainability and reliability of maritime operations. Quality is not just a goal; it is an imperative in marine hose manufacturing.

Recommended Reading