LPG Hose vs. Other Types of Hoses: A Comprehensive Comparative Analysis

Release time:

2025-04-14

Author:

Source:

Abstract

LPG Hose vs. Other Types of Hoses: A Comprehensive Comparative Analysis

Table of Contents

1. Introduction to Hose Types

2. Understanding LPG Hoses

3. Key Characteristics of LPG Hoses

4. Comparison with Other Types of Hoses

4.1 Rubber Hoses

4.2 Plastic Hoses

4.3 Metal Hoses

5. Applications of LPG Hoses

6. Safety Considerations in Ho

LPG Hose vs. Other Types of Hoses: A Comprehensive Comparative Analysis

Table of Contents

- 1. Introduction to Hose Types

- 2. Understanding LPG Hoses

- 3. Key Characteristics of LPG Hoses

- 4. Comparison with Other Types of Hoses

- 5. Applications of LPG Hoses

- 6. Safety Considerations in Hose Selection

- 7. Maintenance and Care for Your Hoses

- 8. Conclusion

1. Introduction to Hose Types

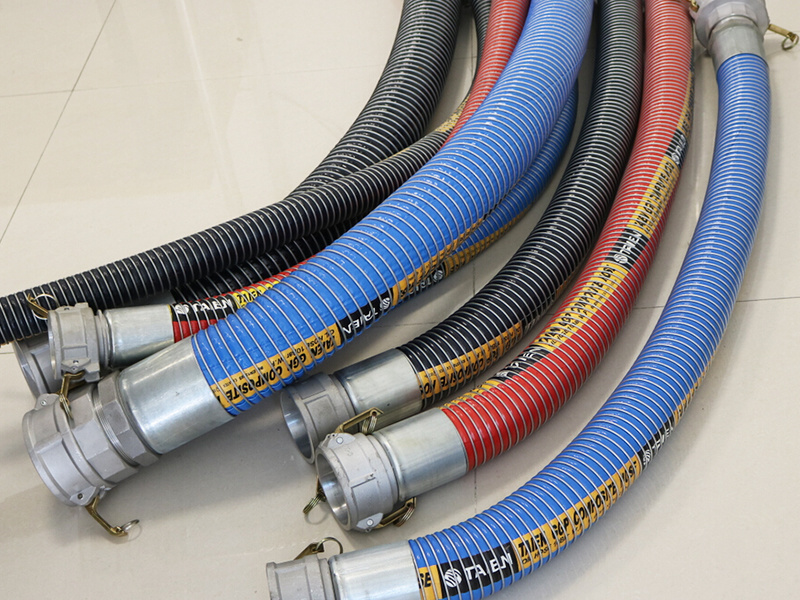

In various industries, the need for reliable hoses is indispensable. When it comes to transferring gases and liquids, choosing the right type of hose can greatly affect efficiency and safety. This article focuses on LPG (liquefied petroleum gas) hoses and compares them with other popular hose types, including rubber, plastic, and metal hoses. Understanding the strengths and weaknesses of each hose type allows businesses and individuals to make well-informed decisions tailored to their specific applications.

2. Understanding LPG Hoses

LPG hoses are specifically designed for transporting liquefied petroleum gas. They are crafted from materials that can withstand high pressures and temperatures, making them ideal for various applications, including heating, cooking, and fueling vehicles. Typically, LPG hoses feature robust inner linings and outer layers to prevent leaks and ensure longevity.

3. Key Characteristics of LPG Hoses

LPG hoses exhibit various unique characteristics, including:

3.1 Durability

These hoses are designed to endure extreme conditions, ensuring a long lifespan even in challenging environments. Their robust construction provides resistance against abrasions, cuts, and other physical damage.

3.2 Flexibility

LPG hoses are flexible, enabling easy maneuverability and installation in confined spaces. This feature is particularly beneficial in industrial settings where equipment may need to be repositioned frequently.

3.3 Temperature Resistance

The materials used in LPG hoses can withstand high and low temperatures, making them suitable for a range of applications, from outdoor cooking to industrial heating systems.

3.4 Safety Features

Many LPG hoses come with additional safety features, such as burst protection and anti-static properties. These enhancements reduce the risk of accidents and ensure safe operation.

4. Comparison with Other Types of Hoses

When selecting a hose, it is essential to compare LPG hoses with other types to determine which best meets your needs.

4.1 Rubber Hoses

Rubber hoses are versatile and commonly used for a wide range of applications. They offer good flexibility and resistance to wear and tear. However, they may not be suitable for high-pressure applications like LPG hoses. Furthermore, rubber hoses can degrade when exposed to certain chemicals or extreme temperatures over time.

4.2 Plastic Hoses

Plastic hoses, often made from PVC or polyurethane, are lightweight and easy to handle. They are resistant to corrosion and chemicals, making them suitable for various applications. However, plastic hoses generally do not have the same temperature and pressure resistance as LPG hoses, which limits their use in high-demand environments.

4.3 Metal Hoses

Metal hoses are designed for high-pressure applications and can withstand extreme temperatures. They are often used in industrial settings for transferring gases and liquids. While they offer superior durability, metal hoses tend to be less flexible and more expensive than LPG hoses, making them unsuitable for some applications.

5. Applications of LPG Hoses

LPG hoses have a wide range of applications, including:

5.1 Residential Use

In homes, LPG hoses are commonly used for connecting gas appliances, such as stoves and heaters, providing a safe and efficient energy source.

5.2 Industrial Applications

In industrial settings, LPG hoses are utilized in heating systems, gas-powered machinery, and construction equipment, ensuring a reliable supply of fuel.

5.3 Agricultural Use

Farmers often use LPG hoses for crop drying, heating barns, and fueling equipment, demonstrating the versatility of these hoses.

6. Safety Considerations in Hose Selection

When choosing a hose for LPG or other applications, safety should always be a priority. Consider the following:

6.1 Pressure Ratings

Ensure that the hose you select is rated for the pressure levels of your specific application. Using a hose that cannot withstand the required pressure may lead to catastrophic failures.

6.2 Material Compatibility

Different substances can react with various materials. Assess the materials used in the hose to ensure compatibility with the substances being transported.

6.3 Regular Inspections

Perform routine inspections of your hoses to identify any signs of wear, damage, or leaks. Keeping hoses in optimal condition is critical for safety.

7. Maintenance and Care for Your Hoses

Proper maintenance is essential for the longevity and performance of your hoses. Here are some tips:

7.1 Cleaning

Regularly clean hoses to prevent the buildup of contaminants that could affect performance. Use a mild detergent and water, avoiding harsh chemicals that could damage the hose material.

7.2 Storage

Store hoses in a cool, dry place away from direct sunlight and extreme temperatures. This practice helps maintain the integrity of the materials.

7.3 Replacement

If you notice significant wear or damage, replace the hose immediately to prevent accidents. Always use hoses that meet the specifications required for your application.

8. Conclusion

In conclusion, understanding the differences between LPG hoses and other types of hoses is vital for making informed decisions tailored to your specific needs. LPG hoses offer durability, flexibility, and safety features that make them suitable for various applications, from residential uses to industrial settings. By considering the unique characteristics of LPG hoses compared to rubber, plastic, and metal hoses, you can ensure you select the best option for your requirements. Regular maintenance and safety checks will further enhance the performance and lifespan of your hoses, providing peace of mind in their use.

Recommended Reading