Troubleshooting Common Issues with Marine Hose in Pneumatic Applications

Release time:

2025-04-17

Author:

Source:

Abstract

Troubleshooting Common Issues with Marine Hose in Pneumatic Applications

Table of Contents

Understanding Marine Hoses in Pneumatic Systems

Common Issues with Marine Hoses

Identifying Leaks in Marine Hoses

Consequences of Damaged Marine Hoses

Prevention Tips for Marine Hoses

Repairing Damaged Marine Hoses

When to Replace Marine Hoses

Frequently Asked Questions

Unde

Troubleshooting Common Issues with Marine Hose in Pneumatic Applications

Table of Contents

- Understanding Marine Hoses in Pneumatic Systems

- Common Issues with Marine Hoses

- Identifying Leaks in Marine Hoses

- Consequences of Damaged Marine Hoses

- Prevention Tips for Marine Hoses

- Repairing Damaged Marine Hoses

- When to Replace Marine Hoses

- Frequently Asked Questions

Understanding Marine Hoses in Pneumatic Systems

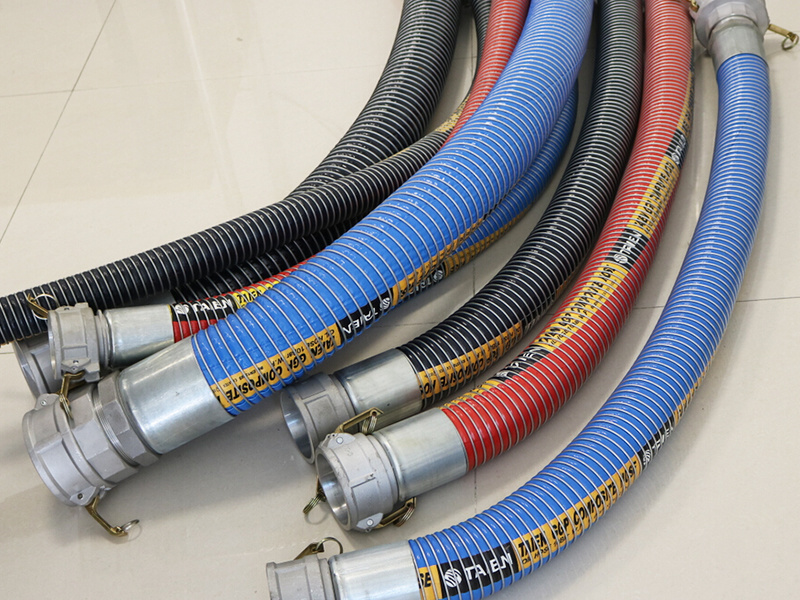

Marine hoses are integral components in various pneumatic applications, particularly in environments where water contact is inevitable. These hoses are designed to withstand harsh marine conditions, including exposure to saltwater, pressure variations, and extreme temperatures. Understanding the specific requirements and characteristics of marine hoses is crucial for ensuring their effective performance.

Marine hoses typically consist of multiple layers, including an inner tube, reinforcement layers, and an outer cover. The inner tube is crafted from materials that resist abrasion and corrosion, making them suitable for transporting fluids under pressure. The reinforcement layers provide additional strength, while the outer cover protects against environmental factors.

The proper selection and maintenance of marine hoses can significantly affect the efficiency and safety of pneumatic systems, particularly in shipyards, marinas, and offshore operations.

Common Issues with Marine Hoses

Despite their robust construction, marine hoses often encounter issues that can jeopardize pneumatic performance. Understanding these common problems can lead to quicker identification and resolution:

1. Air Leaks

One of the most prevalent issues with marine hoses is air leaks. These leaks can occur due to cracks, punctures, or improper fittings. They can lead to reduced system efficiency and increased operational costs.

2. Kinking and Bending

Kinking or excessive bending of marine hoses can restrict airflow, leading to decreased performance. It is essential to install hoses properly and avoid sharp turns.

3. Corrosion and Abrasion

The harsh marine environment can lead to corrosion and abrasion over time. This damage can weaken the hose material, making it prone to failure.

4. Temperature Fluctuations

Marine hoses may experience significant temperature changes, which can affect their flexibility and integrity. Exposure to high temperatures can lead to softening and breakdown, while low temperatures can cause rigidity.

5. Incorrect Sizing

Using hoses that are not appropriately sized for the application can lead to various problems, including pressure loss and increased risk of failure.

Identifying Leaks in Marine Hoses

Detecting leaks in marine hoses is essential for maintaining pneumatic system efficiency. Here are several methods to identify leaks effectively:

1. Visual Inspections

Regular visual inspections of hoses can help identify visible signs of wear, such as cracks, bulges, or abrasions. Look for any signs of fluid leakage around fittings and connection points.

2. Soap Solution Test

Applying a soap solution to the hose and connections can help locate leaks. If bubbles form, it indicates the presence of a leak.

3. Pressure Testing

Conducting pressure tests can help identify leaks by monitoring pressure levels. If there is a drop in pressure, it is likely that a leak is present.

Consequences of Damaged Marine Hoses

The consequences of using damaged marine hoses can be severe, impacting both safety and operational efficiency. Here are some potential outcomes:

1. Reduced System Efficiency

Leaky or damaged hoses can lead to a drop in system pressure and overall performance. This inefficiency can increase energy costs and operational time.

2. Safety Hazards

Compromised hoses can pose significant safety risks, including the potential for fluid spills or sudden bursts. This risk is especially critical in marine environments where personnel safety is paramount.

3. Increased Maintenance Costs

Frequent repairs or replacements of damaged hoses can lead to increased maintenance costs. Proactively addressing hose issues can save time and resources in the long run.

Prevention Tips for Marine Hoses

Preventing issues with marine hoses is essential for ensuring longevity and optimal performance. Here are some effective tips:

1. Regular Inspections

Conducting routine inspections can help identify potential issues before they escalate. Check for signs of wear and tear, particularly in high-stress areas.

2. Proper Installation

Ensure that hoses are installed correctly to avoid kinks and bends. Use appropriate fittings and connections to secure hoses in place.

3. Temperature Management

Monitor temperature variations in pneumatic systems to ensure that hoses remain within their operational limits. Consider insulating hoses in extreme conditions.

4. Use Quality Hoses

Investing in high-quality marine hoses can significantly reduce the likelihood of issues. Look for hoses specifically designed for marine applications.

5. Training Personnel

Training personnel on the proper handling and maintenance of marine hoses can significantly reduce the chances of damage. Provide guidance on best practices for installation and inspections.

Repairing Damaged Marine Hoses

If you encounter damage in your marine hoses, timely repairs are crucial:

1. Assess the Damage

Before proceeding with repairs, assess the extent of the damage. Minor issues may be repairable, while severe damage may require replacement.

2. Use Appropriate Repair Kits

For small leaks or damages, consider using hose repair kits that are designed for marine applications. Follow the manufacturer's instructions for effective repairs.

3. Professional Assistance

In cases of significant damage, it is advisable to consult professionals. Expert technicians can assess and repair hoses effectively, ensuring safety and reliability.

When to Replace Marine Hoses

Recognizing when to replace marine hoses is crucial for system safety and performance:

1. Severe Damage

If hoses exhibit severe cracks, bulges, or wear that cannot be repaired, replacement is necessary.

2. Age of Hoses

Marine hoses have a limited lifespan. If your hoses are approaching or exceeding their recommended lifespan, consider replacing them, even if they appear to be in good condition.

3. Frequent Leaks

If you find yourself repairing hoses frequently, it may be more cost-effective to replace them entirely.

Frequently Asked Questions

1. How often should I inspect my marine hoses?

Regular inspections should be conducted at least once a month, with more frequent checks in high-usage or harsh environments.

2. Can I repair marine hoses myself?

Minor repairs can often be done using appropriate repair kits. However, for extensive damage, it is recommended to seek professional help.

3. What materials are marine hoses typically made from?

Marine hoses are often made from rubber, PVC, or composite materials that resist abrasion and corrosion.

4. How can I extend the lifespan of my marine hoses?

Regular maintenance, proper installation, and avoiding extreme kinks and bends can significantly extend the life of marine hoses.

5. What should I do if I detect a leak?

Immediately isolate the pneumatic system, identify the source of the leak, and either repair or replace the damaged hose as needed.

Conclusion

Understanding and addressing common issues with marine hoses in pneumatic applications is crucial for maintaining optimal performance and safety. By following preventive measures, conducting regular inspections, and knowing when to repair or replace hoses, you can ensure that your pneumatic systems operate efficiently. This proactive approach not only enhances performance but also prolongs the lifespan of your marine hoses, ultimately leading to reduced maintenance costs and improved safety in your operations.

Recommended Reading