The Environmental Impact of Using Oil Hoses: What You Should Know

Release time:

2025-04-20

Author:

Source:

Abstract

The Environmental Impact of Using Oil Hoses: What You Should Know

Introduction to Oil Hoses and Their Usage

Oil hoses are essential components in numerous industries, including automotive, manufacturing, and construction. They facilitate the transfer of oil and other fluids, ensuring that machinery operates efficiently. However, as industries strive for greater efficiency, the environmental implic

The Environmental Impact of Using Oil Hoses: What You Should Know

Introduction to Oil Hoses and Their Usage

Oil hoses are essential components in numerous industries, including automotive, manufacturing, and construction. They facilitate the transfer of oil and other fluids, ensuring that machinery operates efficiently. However, as industries strive for greater efficiency, the environmental implications of using these hoses have come under scrutiny. This article explores the various aspects of oil hoses, their environmental impact, and sustainable alternatives.

Understanding Oil Hoses: Types and Applications

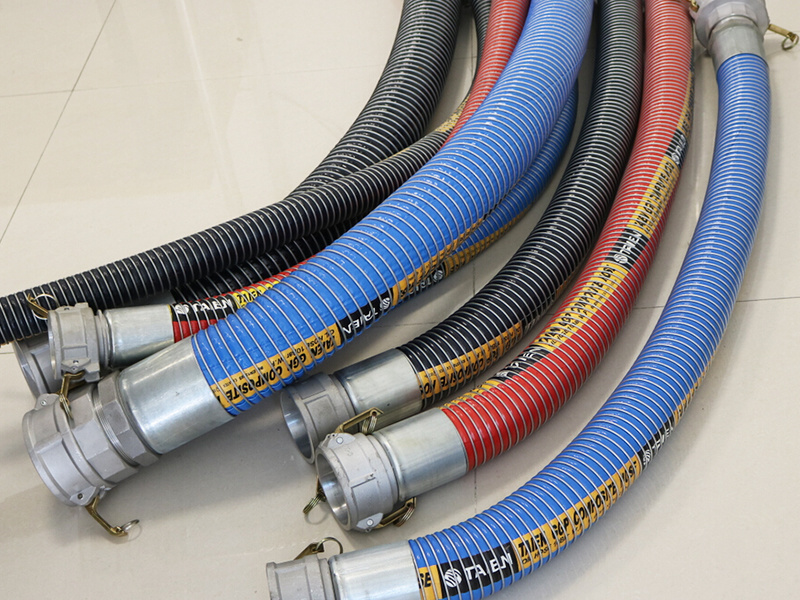

Types of Oil Hoses

Oil hoses vary in design, material, and purpose. The most common types include:

- **Rubber Oil Hoses**: Known for their flexibility and durability, rubber hoses are widely used in automotive applications.

- **PVC Oil Hoses**: Lightweight and resistant to chemicals, PVC hoses are often used in industrial settings.

- **Stainless Steel Braided Hoses**: These hoses offer exceptional strength and resistance to high pressures, making them ideal for critical applications.

Applications of Oil Hoses

Oil hoses play a crucial role in several applications, such as:

- **Automotive Maintenance**: Used for transferring oil during engine servicing.

- **Industrial Equipment**: Facilitating fluid movement in manufacturing processes.

- **Hydraulic Systems**: Ensuring the smooth operation of hydraulic machinery.

Understanding the various types and applications of oil hoses is essential for recognizing their environmental impact.

The Environmental Impact of Oil Hose Production

The production of oil hoses contributes significantly to environmental degradation. This section examines the key factors involved in the manufacturing process.

Resource Extraction and Raw Material Use

The production of oil hoses often involves the extraction of natural resources, including petroleum for rubber and plastics. This process can lead to habitat destruction, pollution, and depletion of non-renewable resources. Additionally, manufacturing facilities consume large amounts of energy, further contributing to greenhouse gas emissions.

Emissions and Pollution During Manufacturing

The manufacturing of oil hoses releases various pollutants into the air and water systems. Volatile organic compounds (VOCs) and hazardous waste generated during production can adversely affect local ecosystems and human health. Rigorous regulations are necessary to mitigate these impacts.

Usage and Maintenance: Environmental Considerations

Leakage and Spill Risks

During their operational phase, oil hoses are susceptible to leaks and spills, which can have severe environmental consequences. Oil spills can contaminate soil and water sources, harming wildlife and disrupting ecosystems. Regular maintenance is crucial for identifying and addressing any signs of wear and tear.

Responsible Usage Practices

To minimize environmental risks associated with oil hoses, users should adopt responsible practices, such as:

- **Regular Inspections**: Conduct frequent checks for leaks or damage.

- **Proper Installation**: Ensure hoses are installed correctly to prevent unnecessary stress and wear.

- **Training and Education**: Educate employees on proper handling and usage to reduce the likelihood of accidents.

Disposal and Environmental Hazards

The disposal of oil hoses presents a significant environmental challenge. Improper disposal methods can result in toxic substances leaching into the soil and water systems.

Challenges in Recycling Oil Hoses

While some components of oil hoses can be recycled, the process is often complicated. Contaminants can hinder recycling efforts, leading to a significant amount of waste ending up in landfills. Innovative recycling technologies are necessary to improve the recycling rates of these materials.

Best Practices for Disposal

To minimize the environmental impact of disposed oil hoses, companies should:

- **Implement a Waste Management Plan**: Ensure proper disposal methods are in place.

- **Partner with Recycling Facilities**: Collaborate with specialized companies that can handle the recycling of oil hoses.

- **Educate Employees on Disposal Options**: Provide training on the importance of responsible disposal practices.

Exploring Sustainable Alternatives to Oil Hoses

As industries become more aware of their environmental impacts, sustainable alternatives to traditional oil hoses are emerging.

Eco-Friendly Materials for Oil Hoses

Several eco-friendly materials can be used to produce oil hoses, including:

- **Biodegradable Plastics**: These materials can decompose naturally, reducing long-term environmental impacts.

- **Recycled Materials**: Utilizing recycled components can significantly decrease resource consumption and waste.

Innovations in Hose Design

Advancements in technology are leading to the development of more efficient hose designs that minimize leaks and improve durability. Innovations such as smart hoses with built-in sensors can provide real-time data on pressure and flow, allowing for better monitoring and maintenance.

The Role of Regulations in Mitigating Environmental Impact

Government regulations play a crucial role in addressing the environmental impact of oil hoses. By enforcing stricter guidelines, industries can be held accountable for their practices.

Current Regulations on Oil Hose Production and Usage

Various regulations govern the production and usage of oil hoses, focusing on:

- **Emissions Standards**: Limiting the amount of pollution generated during the manufacturing process.

- **Safety Regulations**: Ensuring that oil hoses meet specific safety standards to prevent leaks and spills.

The Future of Environmental Regulations

As environmental concerns continue to rise, it is likely that regulations will become even stricter. Industries must stay ahead of these changes by adopting more sustainable practices and technologies.

Conclusion

The environmental impact of using oil hoses is significant and multifaceted. From production to disposal, the entire lifecycle of these hoses poses challenges that industries must address. By adopting sustainable practices, exploring eco-friendly alternatives, and adhering to stringent regulations, we can minimize the negative effects of oil hoses on the environment. Together, we can work towards a more sustainable future that balances industrial efficiency with ecological responsibility.

Frequently Asked Questions (FAQs)

1. What are oil hoses used for?

Oil hoses are primarily used for transferring oil and other fluids in various applications, including automotive maintenance, industrial equipment, and hydraulic systems.

2. How do oil hoses impact the environment?

The production, usage, and disposal of oil hoses can lead to pollution, resource depletion, and habitat destruction, causing significant environmental harm.

3. Can oil hoses be recycled?

While some components of oil hoses can be recycled, the process is often complicated due to contamination. Developing innovative recycling technologies is essential for improving recycling rates.

4. What are the best practices for maintaining oil hoses?

Regular inspections, proper installation, and employee training are crucial for ensuring the longevity and safe operation of oil hoses.

5. What are the sustainable alternatives to traditional oil hoses?

Eco-friendly materials, such as biodegradable plastics and recycled components, along with innovations in hose design, can serve as sustainable alternatives to traditional oil hoses.

Recommended Reading